My Store

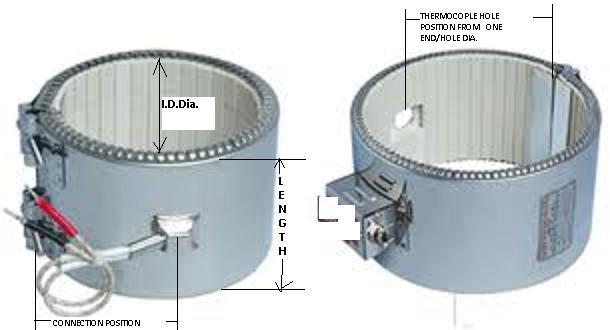

Injection Moulding Machine Heaters

Injection Moulding Machine Heaters

Couldn't load pickup availability

Ceramic heaters are made from SS 304.With high temp.Ceramic materials and original Nichrome wire element. As per correct Technical Design by our Engineers/Experts to withstand heaters for long period. Such heaters are used in many industries like: Plastics, Paper, Rubber, Textile, Pharmaceutical, Packing, Sealing, Printing and many more…These Ceramic heaters are available in various diameters from 2” & in various Lengths as per customer’s requirement.

Advantages:

1. Fast heating compare to mica band heaters so power is SAVE.

2. Withstand at high Temperature.

3. Long life, Durable

4. Flexible, Easy to clamp or unclamp.

5. Due to ceramic used, good electrical insulation achieved.

6 These Ceramic Heaters are designed to provide high performance heating at working temperature of 800°c, the level of performance is achieved from special interlocking ceramic block with nicrome resistance wire wounded through the holes of the ceramic blocks. This method provides heat distribution across the barrel resulting in perfectly heated surface where as the outer sheath in construction in stainless steel with the help of ceramic fiber insulation between the sheath and the element with various terminal options.

Benefits : High Temperature capacity, long service life, low energy cost , heat transfer not affected by surface and can be easily installed and removed.

Application : Barrels and dies of Injection, Blow Molding Machine, Extruders, Autoclaves & Chemical Reactors.

Share